According to a recent study, the push to electrify transportation is accelerating faster than many realize.

By 2030, the electric vehicle charging market will need to expand tenfold to support an estimated 27 million EVs on the road, and possibly 92 million by 2040. That means going from about 4 million charge points today to roughly 35 million in just seven years. Single-family and multifamily homes will make up about 80 percent of that demand.

possibly 92 million by 2040. That means going from about 4 million charge points today to roughly 35 million in just seven years. Single-family and multifamily homes will make up about 80 percent of that demand.

As the EV market increases, so does the need for reliable charging across sectors. For electrical workers, this growth extends well beyond installing chargers. It includes service upgrades, load calculations, system design, maintenance, and long-term planning. Skilled electrical professionals play a critical role in all of these areas.

The EV Market: National & Regional Snapshots

Early clean-energy initiatives, utility programs, and emissions-reduction goals helped accelerate both vehicle ownership and charging deployment across Washington and Oregon. What’s changed is scale. Early EV projects often involved one or two chargers. Now, installations frequently include multi-unit residential buildings, workplace charging hubs, public parking facilities, and fast-charging sites along major routes.

EV Market Numbers: Then & Now

Just a few years ago there were nearly 2.5 million electric vehicles registered in the U.S., with a little over 64,000 charging stations.

According to data from the end of 2025, the U.S. now has 78,361 EV charging stations, supporting 237,134 individual charging ports.

The same report shows the Pacific Northwest’s current numbers:

- Oregon: 1,633 stations and 4,296 ports

- Washington: 2,939 stations and 8,486 ports

- Seattle: Ranks in the top five U.S. cities, with 714 stations and 1,917 ports

4 Types of Charging Levels & Their Electrical Applications

Each charging level has its own specific application in both the private and public sectors, as well as its own speed and energy output. Understanding their roles in an expanding EV market is crucial for the electrical industry.

- Residential Level 2 Charging

Most single-family homes use Level 2 chargers operating on 240V service, with outputs up to approximately 9.6 kW. These systems are designed for overnight charging and often require panel capacity checks, load calculations, and code-compliant installation. - Workplace and Office Charging

Commercial Level 2 chargers are typically pedestal-mounted and hardwired. While they operate on the same voltage as residential units, shared use and longer dwell times require careful circuit planning and consideration for future expansion. - Public Parking Charging

Chargers installed in garages and public lots range from higher-power Level 2 units to DC fast chargers up to 50 kW. These installations frequently involve dedicated circuits, upgraded service, and coordination with utilities. - Highway and On-the-Go Fast Charging

DC fast chargers along highways deliver up to 150 kW and require three-phase service, robust protection, and thoughtful grid impact planning. These systems represent some of the most complex EV installations.

Electrical Contractors Are Key to Meeting EV Infrastructure Needs

As electric vehicles become more common, the demand for reliable charging infrastructure is increasing. Electrical contractors have the expertise to address the challenges this growth brings and ensure systems are safe, efficient, and ready for the future.

- Expansion of Fast-Charging Networks

Drivers expect quick, convenient charging similar to fueling stations. Meeting that expectation requires electricians experienced with high-load systems and uptime requirements. - Modernizing Aging Infrastructure

Many buildings and transit systems were not designed for EV demand. Panel upgrades, service increases, and system retrofits are becoming standard scopes of work. - Ongoing Maintenance & Repairs

Copper theft and equipment damage are driving up repair needs. Plus, many EV stations use outdated components, making replacement parts hard to find. Electricians ensure these systems stay safe and operational.

As EV charging becomes a standard fixture in homes and communities, electrical professionals with the right expertise are shaping the future of this essential infrastructure.

Keep Current with NECA-IBEW Local 48

The NECA-IBEW Local 48 partnership is a community where you can learn, share, and stay connected as the industry evolves. Membership provides access to continuing education, on-the-job training programs, and valuable support networks.

Visit our membership pages for the Oregon-Columbia Chapter of NECA or IBEW Local 48 to learn more.

the electrical industry, this usually means using data from power grids, equipment, buildings, and job costs to improve efficiency and reliability.

the electrical industry, this usually means using data from power grids, equipment, buildings, and job costs to improve efficiency and reliability.

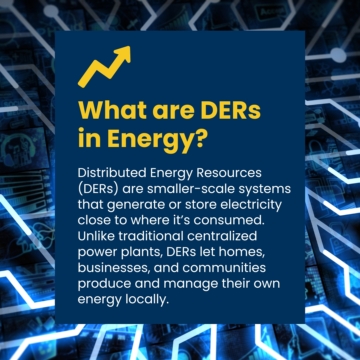

traditional centralized power plants, DERs allow local communities and businesses to produce their own energy.

traditional centralized power plants, DERs allow local communities and businesses to produce their own energy.

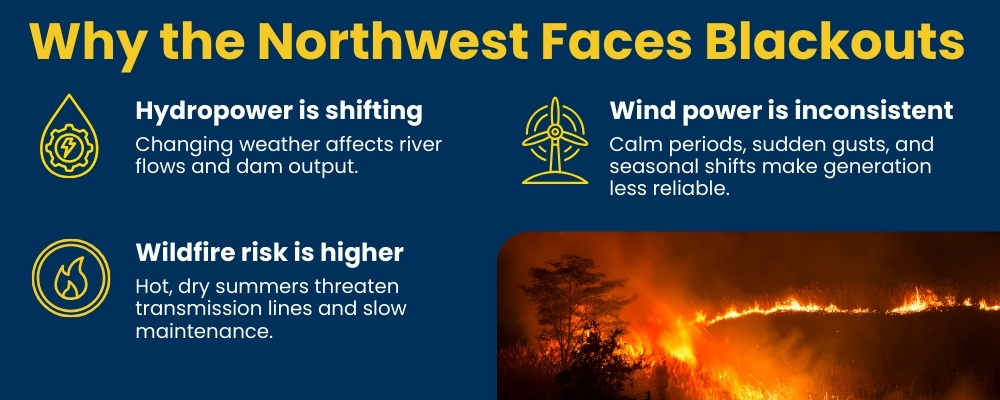

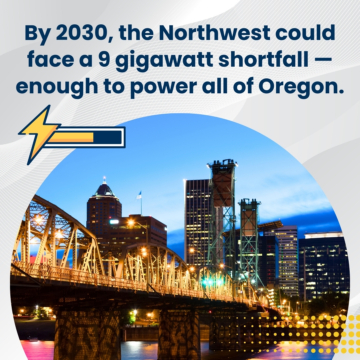

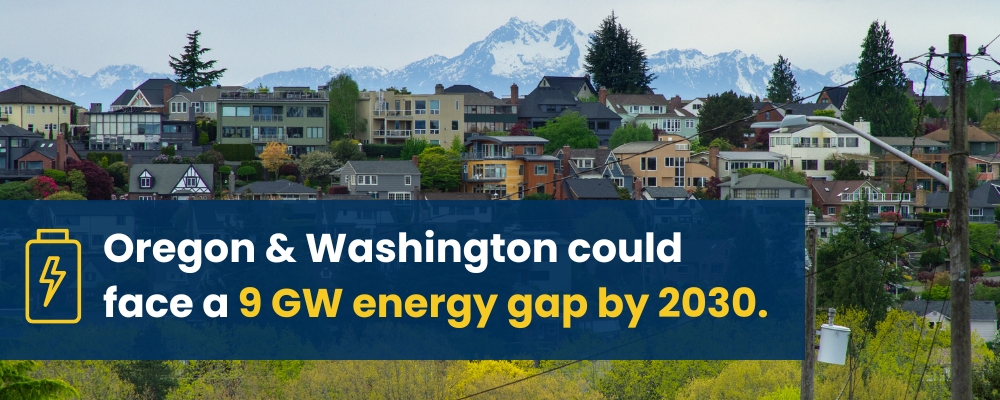

Northwest. Electricity demand is growing fast, and some of the older transmission systems are feeling the pressure. Utilities are looking at imports, adjusting pricing, and planning upgrades to keep things running smoothly. In Oregon, recent rate increases show how infrastructure and weather can affect energy costs.

Northwest. Electricity demand is growing fast, and some of the older transmission systems are feeling the pressure. Utilities are looking at imports, adjusting pricing, and planning upgrades to keep things running smoothly. In Oregon, recent rate increases show how infrastructure and weather can affect energy costs.

driving up vacancy rates and halting new construction. However, the Pacific Northwest continues to be a hub for data center development and is holding firm. Hillsboro has the lowest data center vacancy rate,

driving up vacancy rates and halting new construction. However, the Pacific Northwest continues to be a hub for data center development and is holding firm. Hillsboro has the lowest data center vacancy rate,