JH Kelly Delivers Electrical Solutions for Columbia Memorial Hospital Expansion

Columbia Memorial Hospital (CMH) in Astoria, Oregon, is undergoing a major expansion to meet the growing healthcare needs of the community. The ambitious project includes a four-story, 182,000 SF addition to the existing hospital, which will feature an expanded emergency department, state-of-the-art operating rooms, larger patient rooms, and additional space for mechanical equipment.

The project will also include resiliency features, such as the region’s first Tsunami Vertical Evacuation Structure (TVES) and a deep pile foundation, ensuring the facility can remain operational during natural disasters. It will be one of the largest construction projects in Clatsop County’s history. This four-year capital improvement initiative will expand hospital services, attract new healthcare providers, and integrate the latest technology to better meet the community’s health needs.

The project team includes ZGF Architects, Skanska USA, and electrical contractor JH Kelly, responsible for overseeing and executing all phases of the electrical work for the expansion.

JH Kelly has partnered with Skanska on several projects, with their collaboration dating back to 2019. They served as the Electrical Trade Partner on three school projects for the Astoria School District between 2020 and 2022, modernizing and expanding the schools. As the projects wrapped up, the opportunity for the Columbia Memorial Hospital project emerged. Skanska was awarded the project, and the strong working relationship built over the previous years helped pave the way for this new venture.

JH Kelly’s Role in the Expansion

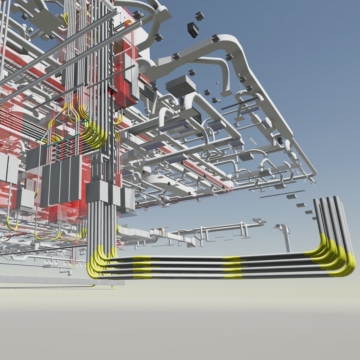

JH Kelly is responsible for all aspects of electrical work on the project, including a complex emergency system, power distribution, lighting and lighting control, low-voltage cabling, and fire alarm systems. While access control, security, and audio-visual systems are managed directly by the owner, JH Kelly handles the raceways, pathways, and power requirements to activate these systems. The majority of the electrical work, covering everything related to electricity, falls under their scope. This includes generator systems, fuel management system, UPS units, and specialty equipment in the imaging suites.

Supporting the Local Community

When selecting a general contractor and trade partners for the Columbia Memorial Hospital (CMH) project, CMH prioritized companies with a local presence to benefit the community. Although it wasn’t a contractual requirement, CMH emphasized the importance of positively impacting the North Coast community. JH Kelly’s dedication to using local labor and subcontractors aligned with this goal. Furthermore, JH Kelly ensured that CMH would have access to local contractors for ongoing maintenance, promoting long-term support and a sustainable, locally-driven service network.

“Astoria is a coastal town, so it’s a bit off the beaten path from most major cities. But for us, it’s local. It’s home, and we take a lot of pride in that.” ~ Bob Breien, Sr. Project Manager JH Kelly

In past projects, JH Kelly has consistently prioritized working with the local community. For example, in 2021, JH Kelly, in partnership with Skanska, provided temporary power for Astoria High School’s senior prom, held outdoors due to COVID restrictions. Project superintendent Kristian Fremstad led efforts to secure a generator and lighting, with the team donating their time for setup and takedown. JH Kelly also strengthened its local business support by partnering with Bogh Electric, an IBEW Local 48 contractor, building on previous collaborations with local businesses during the Astoria school projects.

Special Considerations for the CMH Project

The Columbia Memorial Hospital project has several key considerations, with the most critical being its tsunami vertical evacuation refuge structure. Situated in the Cascadia Subduction Zone, the hospital must remain operational even during a major earthquake or tsunami.

“What’s unique about this project is that it’s designed not just to survive but to serve as a gathering point and a resource for the entire community. ~ Abe Ott, JH Kelly Director of Marketing

To ensure this, utilities and generators are placed on the 4th and 5th floors, above the tsunami zone, keeping them intact during potential disasters. In case of power loss, the hospital’s generator system is designed to take over immediately, with an 50,000-gallon seismically-supported fuel tank ensuring uninterrupted power for as long as needed.

Additionally, flywheel UPS systems provide instant power transfer, ensuring that critical systems continue to operate without interruption, even if utility power is lost. This design adds an extra layer of resilience to the project, ensuring the hospital can function continuously, providing essential support during catastrophic events.

Work Currently in Progress

The project is currently focused on key tasks such as utility relocations, parking lot revisions, temporary helipad, site lighting, and providing temporary power. Asphalt and lighting in front of the existing cancer center are finished, and work is progressing on a road to bedrock for structural stability.

The helipad is being temporarily relocated due to its position in the utility relocation zone, ensuring Life Flight operations continue smoothly during construction. It will be moved to the top of the new hospital towards the project’s completion.

Behind the scenes, pre-construction efforts, led by Bob Breien, JH Kelly’s Electrical Sr. Project Manager, are focused on budgeting, constructability, value engineering, and coordination. Quentin Kauppi, JH Kelly’s Electrical BIM/Prefab Manager, leads clash detection and virtual design through the BIM coordination process, allowing off-site prefabrication for schedule efficiency. With the project timeline compressed, prefabrication helps keep the schedule on track.

Long lead times for critical components, like generators, are being managed proactively. Due to a 90-week manufacturing process, the generators were submitted on, approved, and procured early during preconstruction, to address supply chain challenges and ensure timely delivery.

Next Steps for the Columbia Memorial Hospital Project

The final completion date for the project is expected in spring of 2028, marking the completion of Phase 1B, which involves the new 182,807-square-foot hospital. Following that, the focus will shift to retrofitting and remodeling the existing hospital to integrate it with the new facility’s systems, ensuring seamless functionality between the two.

About JH Kelly

JH Kelly is a fourth-generation construction company that self-performs work across Washington, Oregon, Idaho, and Montana. With a skilled workforce that includes plumbers, pipefitters, electricians, ironworkers, boilermakers, millwrights, carpenters, sheet metal workers, laborers, and operators, JH Kelly has built a reputation for delivering high-quality, diverse construction services.