Exciting progress is underway at the future home of the Hillsboro Hops, a state-of-the-art ballpark set to redefine the fan experience in Oregon.

Slated for completion in 2026, the new stadium is being built with more than baseball in mind. Designed as a vibrant, multi-use venue, the ballpark will offer a 360-degree wraparound concourse, a lively beer garden, and a dynamic food hall featuring six unique dining options. Beyond game day, the stadium will serve as a year-round entertainment hub, hosting over 10 Live Nation concerts and community events annually.

The Opening Pitch

When Mortenson began assembling its team for the highly anticipated Hillsboro Hops Ballpark, where they are serving as the design-builder, they knew they needed the right electrical partner with the expertise, innovation, and energy to match the scale of the project. OEG was invited to bid and quickly emerged as the standout choice due to their track record of forward-thinking electrical construction solutions, as well as their ability to provide electrical engineering and design services directly through their in-house engineering department.

From the very first roundtable discussion, OEG brought passion and purpose. That mindset fueled a series of strategic planning sessions where OEG outlined its approach, resources, and unwavering determination to win the job.

“We came in ready to knock it out of the park. I’ve never been on a job where morale has been so high on a project ,” said a representative from the OEG team.

With a deep portfolio spanning high-tech, commercial, and service work, OEG demonstrated it had the scale and experience to handle a project of this magnitude. The company’s extensive prefab capabilities, supported by dedicated facilities and strong material storage and procurement systems, gave OEG a clear operational edge.

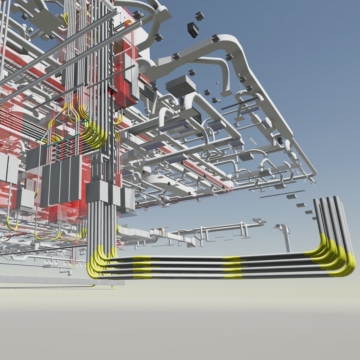

OEG’s standout BIM (Building Information Modeling) department also played a key role. Their ability to create detailed 3D models has enabled seamless collaboration and precise installation, helping the team bring the complex stadium design to life efficiently and accurately.

A long-standing relationship with Mortenson further strengthened OEG’s position. Built on trust, communication, and shared problem-solving, the partnership set the tone for a collaborative, solution-driven build.

A Project That Hits Home

For OEG, the Hillsboro Hops Ballpark is more than just another job. It is a point of pride for the entire team. As a high-profile community project located in their own backyard, this stadium build holds personal significance. Many of the electricians on-site are longtime locals who’ve attended Hops games with family and friends, and now have the unique opportunity to help build its future home. OEG even hosts its company picnics at the Hops stadium, making the connection that much more meaningful.

“This is the kind of project you talk about for years,” said an OEG project lead. “Our team has been excited about it since day one. It’s something we get to show off and be proud of.”

Powering the Vision

OEG plays a critical role in bringing the Hillsboro Hops’ new ballpark to life. From core infrastructure to high-end amenities, their team is responsible for installing the 3,000-amp and 1,200-amp services, all branch panels, interior and site lighting, fire alarm systems, pathways for security, EV chargers, AV systems, and more.

To support the stadium’s state-of-the-art features, including a 360-degree concourse, food hall, and beer garden, OEG has integrated tailored solutions such as chases for beer lines, air curtains, and custom lighting in the premium club area. Their scope also includes speaker systems across concourse and club levels, and dedicated show power infrastructure to support concerts and other large-scale events.

Throughout the project, OEG has prioritized both performance and appearance. A key focus has been on concealment, making much of the conduit “disappear” to maintain the clean, high-end look of the space. This has involved routing conduit in deck slabs beneath concrete and high above ceilings. The team also worked closely with inspectors early in the process to confirm placement strategies that support both code compliance and visual impact. Every installation is purposeful and carefully considered.

OEG’s prefabrication capabilities have further streamlined construction. By building components off-site in their prefab shops, the team has reduced installation time, improved quality, and minimized on-site congestion.

Early in the build, OEG prefabricated underground conduit racks for the switchgear and assembled custom racks for panels and transformers. Conduit ranging from 2 to 4 inches was bent in-shop for major systems, including one-line distribution and the low-voltage backbone.

As the project moves into its final phase, device kits with labels and cover plates are being assembled off-site and delivered ready for installation. This allows field crews to complete rooms efficiently and with consistent quality.

Coordinating Complex Systems in an All-Weather Venue

Designing for an all-weather venue has presented unique challenges. With multiple roof levels and exposed areas, routing electrical systems required detailed planning to avoid waterproofing conflicts. Certain floors act as both surface and roof, demanding precise conduit placement and coordination across trades.

Unlike a traditional building with a single roof structure, the Hillsboro Hops ballpark features multiple split slabs with membranes, foam, and additional concrete layers. This complex design required OEG to carefully plan and route penetrations to maintain the integrity of the waterproofing system, particularly in high-traffic areas such as the concourse, where numerous concession lines converge.

The premium level also required creative electrical solutions. Floor boxes had to be installed in coordination with accordion walls and drainage systems, leaving little room for error.

To manage these complexities, OEG relied on its robust BIM capabilities to visualize system layouts in 3D and coordinate across trades. Daily sync meetings and pull-plan scheduling helped minimize trade stacking and avoid overlap between crews, improving both safety and workflow.

Enhancing the Fan Experience Through Craftsmanship

OEG’s commitment to quality is reflected in every conduit run, lighting system, and connection point throughout the stadium. The team is focused on delivering excellent craftsmanship and precise coordination to ensure the stadium is not only ready on time but built to impress.

“We take a lot of pride in what we’re building here,” said an OEG representative. “The systems we’re installing will directly impact the fan experience, and we want that experience to be seamless, exciting and memorable.”

Powered by Partnership: 75+ Years with NECA/IBEW

OEG’s longstanding relationship with NECA and IBEW continues to shape its success. This trusted partnership ensures OEG has access to a highly skilled, trained workforce and the support to deliver complex projects at the highest standard.

Working closely with NECA/IBEW has helped OEG stay ahead of evolving industry demands and maintain a consistent pipeline of talent through strong apprenticeship programs and workforce development initiatives.

About OEG

Founded in 1947, OEG is one of the largest electrical contracting companies in the Pacific Northwest, known for delivering high-quality, innovative solutions across commercial, industrial, and high-tech sectors. In 2001, OEG was acquired by Everus Construction Group, a national provider of electrical and mechanical, and transmission and distribution services. Backed by Everus’ resources and financial strength, OEG continues to lead complex projects with a commitment to safety, craftsmanship, and community.

Visit OEG on Facebook, LinkedIn, and Instagram.